Dipra Engineers are a leading multi – disciplinary engineering company, with specialized expertise in manufacture of Material hoists, since 1999.

Over the years, Dipra have further expanded into numerous fields in Supply, Installation and Commissioning of Wood fired, Diesel, and Electric Steam Boilers, a wide range of Escalators, Passenger lifts and Home lifts, EOT Cranes, Hydraulic lifters, Dock Levelers, a full range of Manual and Electric Hoists, Construction Hoists, Dockyard ship building shed travelers, Car parking systems, Dumbwaiters and Wheel chair lifts.

The Company has extended their business by establishing a new division for Construction Equipment for the civil sector. The product range includes Fully Hydraulic and manual tilting concrete mixers, Oil bath type Tamping Rammers, Plate Compactors, Power trowel machines with additional attachments for floor finishing reducing skilled labor requirements, Asphalt and concrete floor cutting machines, Poker Vibrators with the patented “Ergoviplus” solenoid switching system, Mechano / Electrical Bar bending machines & Electric Construction hoists which are manufactured by “Fastverdini, Altrad Italia & TRIAX”, Italy. The equipment’s are durable, superior and have an outstanding “value for money” proposition for all contractors.

Dipra Engineers operates an island wide service network and provides strong warranties on all their equipment’s and arranges credit facilities for their clients through the banking sector (T & C apply).

Dipra’s aftersales service teams are fully factory trained technical staff with back office support of maintenance management systems. Dipra meets specific needs of each range of customers and stand behind what they build and import and supply through recognized overseas partners with full service backup. Through prudent planning, dedicated work, and technical expertise coupled with “customer – centric” culture, Dipra moves forward in lifting the bar towards greater consumer service excellence.

1. Concrete Mixer (Electric/Engine/Hydraulic)

Concrete mixers “CE”

All our Concrete mixers are designed manufactured in accordance with the “European Directives for Machine” and the most stringent international quality standards. On request all machines can be equipped with bearing pneumatic tiers for towing. In petrol or diesel engine models the cabin is larger.

Concrete Mixer “CE250/300/350”

Concrete Mixer “CE250” Concrete Mixer “CE300” Concrete Mixer “CE350”

Concrete Mixer “CE350” Petrol/Diesel Engine Cabin

All the Concrete Mixers can be equipped with petrol and diesel engine

MODEL |

CODE |

CAPACITY (LTR) |

RPM |

MOTOR |

MOTOR TYPE |

WEIGHT (KGS) |

LENGTH (CM) |

WIDTH (CM) |

HEIGTH (CM) |

|

CE 350 |

2ST350N.000.V |

350 |

26 |

190 |

180 |

92 |

155 |

||

|

2ST350B.M15.V |

350 |

26 |

HP. 1.5 |

SINGLE PHASE |

206 |

180 |

92 |

155 |

|

|

2ST350B.M20.V |

350 |

26 |

HP. 2.0 |

SINGLE PHASE |

206 |

180 |

92 |

155 |

|

|

2ST350.BT15.V |

350 |

26 |

HP. 1.5 |

THREE PHASE |

206 |

180 |

92 |

155 |

|

|

2ST350B.P9.V |

350 |

26 |

PETROL CV.9 |

HONDA |

220 |

185 |

92 |

155 |

|

|

2ST350B.D9.V |

350 |

26 |

DIESEL CV.9 |

HONDA |

220 |

185 |

92 |

155 |

|

|

CE 300 |

2ST300N.000.V |

300 |

26 |

184 |

180 |

92 |

155 |

||

|

2ST300B.M15.V |

300 |

26 |

HP. 1.5 |

SINGLE PHASE |

204 |

180 |

92 |

155 |

|

|

2ST300B.M20.V |

300 |

26 |

HP. 2.0 |

SINGLE PHASE |

204 |

180 |

92 |

155 |

|

|

2ST300.BT15.V |

300 |

26 |

HP. 1.5 |

THREE PHASE |

204 |

180 |

92 |

155 |

|

|

2ST300B.P9.V |

300 |

26 |

PETROL CV.9 |

HONDA |

218 |

185 |

92 |

155 |

|

|

2ST300B.D9.V |

300 |

26 |

DIESEL CV.9 |

HONDA |

218 |

185 |

92 |

155 |

|

|

CE 250 |

2ST250N.000.V |

250 |

26 |

145 |

180 |

92 |

155 |

||

|

2ST250B.M15.V |

250 |

26 |

HP. 1.5 |

SINGLE PHASE |

165 |

180 |

92 |

155 |

|

|

2ST250B.M20.V |

250 |

26 |

HP. 2.0 |

SINGLE PHASE |

165 |

180 |

92 |

155 |

|

|

2ST250B.T15.V |

250 |

26 |

HP. 1.5 |

THREE PHASE |

165 |

180 |

92 |

155 |

|

|

2ST300B.P9.V |

250 |

26 |

PETROL CV.9 |

HONDA |

185 |

185 |

92 |

155 |

|

|

2ST300B.D9.V |

250 |

26 |

DIESEL CV.9 |

HONDA |

185 |

185 |

92 |

155 |

|

|

CE 200 |

2ST200N.000V |

200 |

110 |

140 |

80 |

140 |

|||

|

2ST200B.M10.V |

200 |

26 |

HP. 1.0 |

SINGLE PHASE |

134 |

150 |

80 |

140 |

|

|

2ST200B.M15.V |

200 |

26 |

HP. 1.5 |

SINGLE PHASE |

134 |

150 |

80 |

140 |

|

|

2ST200B.T15.V |

200 |

26 |

HP. 1.5 |

THREE PHASE |

134 |

150 |

80 |

140 |

|

|

2ST200B.P5.V |

200 |

26 |

PETROL CV.5 |

HONDA |

145 |

150 |

80 |

140 |

|

|

2ST200B.D5.V |

200 |

26 |

DIESEL CV.5 |

HONDA |

150 |

150 |

80 |

140 |

2. Construction Hoist (300kg/500kg)

CONSTRUCTION HOIST - 300Kg/500Kg

CONSTRUCTION HOIST COMPLETE RANGE SPECIFICATON CHART

|

TYPE |

LOAD |

ROPE |

STEEL CABLE |

BREAKING STRENGTH |

AV.LIFTING SPEED |

ELECTRIC MOTOR |

OVERALL DIMENSION W x L x H |

HOIST WEIGTH |

PHASE |

|

Kg. |

Mt. |

Mm. |

kN. |

Mt/min. |

kW. |

mm. |

Kg. |

=== |

|

|

MA/MP200 |

200 |

25 |

5 |

16.08 |

19 |

0.75 |

200x775x380 |

38 |

1 |

|

TE 200 |

200 |

25 |

5 |

16.08 |

23 |

0.75 |

200x775x380 |

35 |

1 |

|

MV 200 |

200 |

40 |

5 |

16.08 |

40 |

1.1 |

270x780x500 |

50 |

1 |

|

M 290 |

300 |

25 |

6 |

24 |

21 |

1.1 |

270x780x500 |

52 |

1 |

|

T 300 |

300 |

25 |

6 |

24 |

28 |

1.5 |

270x780x500 |

49 |

3 |

|

M 500 |

500 |

25 |

7 |

31.66 |

21 |

1.5 |

270x780x500 |

58 |

1 |

|

T 500/E |

500 |

25/40 |

7 |

31.66 |

28 |

2.5 |

270x780x500 |

57 |

3 |

|

T 500 |

500 |

25/40 |

7 |

31.66 |

18 |

3 |

270x780x500 |

92 |

3 |

|

MD 500 |

500 |

28/30 |

6 |

24 |

11 |

1.1 |

270x780x500 |

58 |

1 |

|

T 800 |

800 |

25/40 |

8 |

44.43 |

18 |

3 |

860x320x545 |

95 |

3 |

|

MD 800* |

800 |

25 |

7 |

31.66 |

11 |

1.5 |

270x780x500 |

73 |

1 |

|

TD 950/E* |

950 |

25/70 |

7 |

31.66 |

14 |

2.5 |

270x800x500 |

72 |

3 |

|

TD 950* |

950 |

25/40 |

7 |

31.66 |

9 |

3 |

400x900x450 |

108 |

3 |

|

TD 1800 |

1800 |

25/40 |

8 |

44.43 |

9 |

3 |

860x320x545 |

108 |

3 |

|

SL 500 |

500 |

25/40 |

7 |

31.66 |

30 |

Gasoline |

450x1200x580 |

70 |

- |

|

DL 500 |

500 |

25/40 |

7 |

31.66 |

30 |

Diesel |

450x1200x580 |

80 |

- |

|

SLD 1000* |

950 |

25/40 |

7 |

31.66 |

15 |

Gasoline |

450x1200x580 |

95 |

- |

|

DLD 1000* |

950 |

25/40 |

7 |

31.66 |

15 |

Diesel |

450x1200x580 |

105 |

- |

3. Floor Cutter

ASPHALT CONCRETE CUTTING SAWS (SAW LM SERIES)

SAW LM / 400-450

• With 9 HP Honda Petrol Engine, GX 270 and max diamond blade Ø 400mm; depth 135mm

• With 13 HP Honda Petrol Engine, GX 390 and max diamond blade Ø 450mm; depth 160mm

• Recoil starting

• 20 Lt. removable fiberglass water tank

• Advance by hand

• Cutting depth control by hand wheel

• Quick water refill

• Overall dimensions cm 60x102x87 (h)

• Total weight: 95 Kg

• Patented Depth Indicator.

Water refill without removing the tank

LM SAW

Features and Advantages

New lifting arm in a balanced position.

Quick water pipe disconnection to make tank

Removal easier and a double water tap.

PATENTED DEPTH INDICATOR

A new depth indicator unique of its kind:

1. Easy to spot and well protected.

2. Gives a clear and accurate reading in centimeters for two diamond blade diameters.

In the absence of a depth indicator, manual measuring with a metric rule is never exact because the groove cut is always full of cutting debris and cleaning it is never complete or easy, so the true cutting depth is never known and in practice this result in a deeper cut than necessary being made.

A cut deeper than requested has following inconveniences:

- Higher diamond blades wear.

- Longer cutting operation.

- The saw’s engine suffers a stronger effort lowering its standards life.

- Higher fuel consumption.

- Higher fuel maintenance expenses of both engine and saw.

- More servicing costs for the machine and the motor.

ASPHALT CONCRETE CUTTER LM SERIES SPECIFICATION TABLE

|

Model |

LM 400 - Honda |

LM 400 – Robin Subaru |

LM 450 – Honda |

LM 450 – Robin Subaru |

|

Model Code |

PFSELM03 |

PFSELMR3 |

PFSELM15 |

PFSELMR6 |

|

Max disk dia. mm |

400 |

400 |

450 |

450 |

|

Max cutting depth mm |

135 |

135 |

160 |

160 |

|

Operating weight Kg. |

91 |

91 |

95 |

95 |

|

Motor |

Honda petrol engine GX270 |

Robin Subaru petrol engine EX27 |

Honda petrol engine GX390 |

Robin Subaru petrol engine EH41 |

|

Motor power Kw (Hp) |

6.6 (9.0) |

6.6 (9.0) |

9.6 (13.0) |

9.9 (13.5) |

|

Starting |

Recoil |

Recoil |

Recoil |

Recoil |

|

Water tank capacity 20Ltr. |

20 |

20 |

20 |

20 |

|

Operating advancement |

By hand |

By hand |

By hand |

By hand |

|

Depth adjustment |

Hand-wheel |

Hand-wheel |

Hand-wheel |

Hand-wheel |

|

Direction corrector |

- |

- |

- |

- |

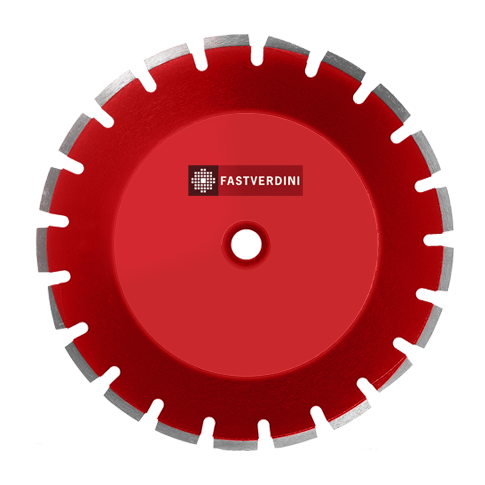

FLOOR CUTTING SAW

ASPHALT SERIES

DRY/WET CUTTING

Professional quality with diameter between 300 and 600 mm.

Model code - DISCHI1

WET CUTTING

Super professional quality with diameter between 300 and 800 mm.

Model code - DISCHI2

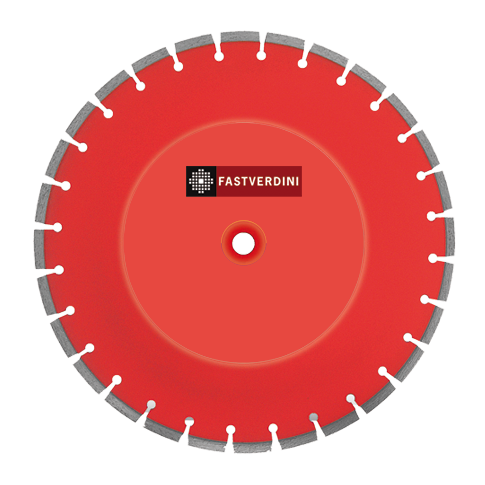

FRESH CONCRETE SERIES

CUTTING WITHING 48 HOURS

Super professional quality with diameter between 300 and 350 mm.

Model code - DISCHI5

CUTTING AFTER 48 HOURS

Super professional quality with diameter between 300 and 350 mm.

Model code - DISCHI6

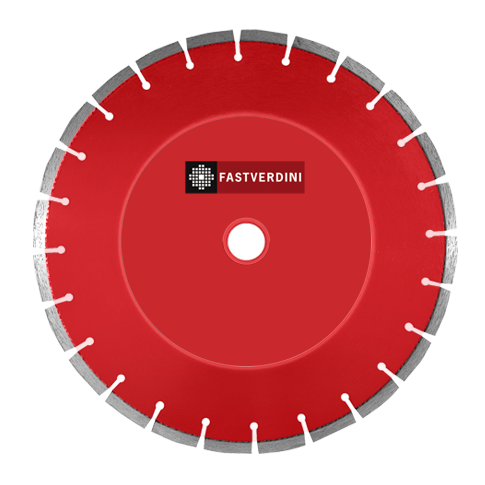

ASPHALT and CONCRETE SERIES

DRY/WET CUTTING

Laser cutting - Super professional quality with diameter between 300 and 450 mm.

Model code - DISCHI7

4. Plate Compactor

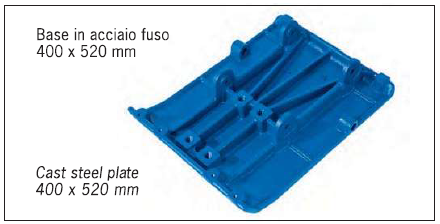

Heavily ribbed cast steel base with rounded edges. To withstand a very powerful vibrating mass and therefore strong vibration.

The rounded edges are ideal for asphalt as they do not leave lines. ACCESSORIES: water system for working on asphalt or rubber mat for self-locking.

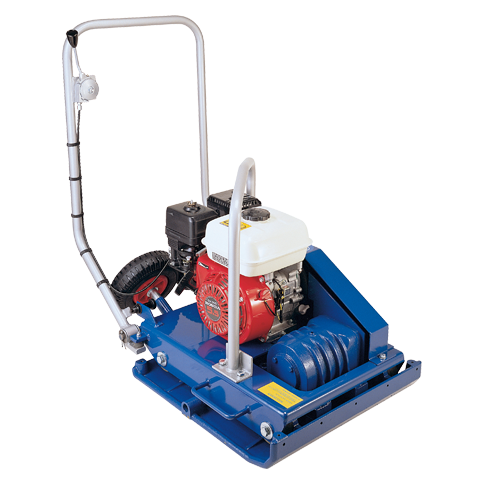

SB 28 with two wheels. 14Ltr. Water tank and lifting hook upon request. Weight 83Kg.

Heavily ribbed cast steel base: can withstand a very powerful vibrating mass. The wide-ranging rounded edges do not leave scratches on the asphalt.

SB 28 plate 400 x 520mm. Weight 74Kg.

With Honda petrol engine 5.5HP

With Robin Subaru Petrol engine 4.5HP

With 14Ltr water tank and lifting hook upon request.

With built-in wheels and lifting hook upon request. SB 28 in normal version equipped with freewheels.

|

MODEL |

CENTER FORCE (KN) |

WEIGHT (KG) |

PLATE WIDTH (MM) |

PLATE LENGTH (MM) |

FREQ. Hz |

MOTOR/ENGINE |

WORKING SPEED |

PENETRATION CM – INCH |

DIRECTION |

WHEELS |

|

SM 25 |

11 |

62 |

350 |

526 |

80 |

Petrol HP 4.5/5.5 |

m/1=20 |

16 - 6.3 |

Forward |

Yes |

|

SM 29 |

14 |

87/123 |

500 |

526 |

80 |

Petrol HP 4.5/5.5

Diesel HP 4.8 |

m/1=20 |

16 - 6.3 |

Forward |

Yes |

|

SB 28 |

14.2 |

74 |

400 |

520 |

80 |

Petrol HP 4.5/5.5 |

m/1=20 |

22 - 8.7 |

Forward |

Yes |

|

SC 30 |

17 |

95/107 |

300/500 |

630 |

90 |

Petrol HP 5.5 |

m/1=20 |

30 - 11.8 |

Forward |

Optional |

|

AC 32 |

22.5 |

107 |

520 |

570 |

100 |

Petrol HP 5.5/6.0 |

m1=20 |

33 - 13 |

Forward |

Yes |

|

SD 28 |

14.2 |

92 |

400 |

520 |

80 |

Diesel HP 4.6/4.8 |

m/1=20 |

22 - 8.7 |

Forward |

Yes |

|

DA 32 |

22.5 |

132 |

520 |

570 |

100 |

Diesel HP 4.6/4.8 |

m/1=20 |

36 - 14.2 |

Forward |

Yes |

|

DC 50 |

23 |

132/144 145/157 |

500/660 |

620 |

88 |

Petrol HP 6.5

Diesel HP 4.6/4.8 |

m/1=22 |

45 - 17.8 |

Forward |

Yes |

|

AR 48 |

25 |

100/110 |

400/560 |

600 |

80 |

Petrol HP 6.5 |

m/1=20 |

30 - 11.8 |

Forw/Reve |

Yes |

|

AR 52 |

25 |

130/140 |

400/560 |

600 |

80 |

Diesel HP 4.6/4.8 |

m/1=20 |

30 – 11.8 |

Forw/Reve |

Yes |

|

AR 63 |

30 |

213/233 226/246 232/252 |

450/650 |

760 |

80 |

Petrol HP 6.5

Diesel HP 4.6/4.8

Diesel HP 6.7/7.5 |

m/1=20 |

50 – 19.7 55 – 21.6 |

Forw/Reve |

Yes |

|

AR 80 |

40 |

370/400 |

450/630 |

900 |

80 |

Diesel HP 10 |

m/1=20 |

70 – 27.6 |

Forw/Reve |

No |

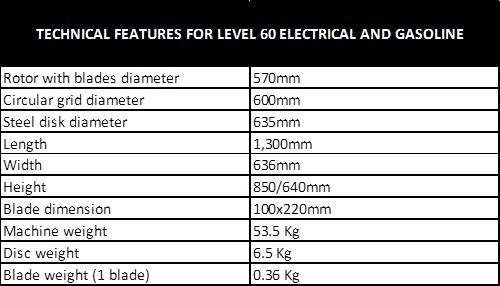

6. Power Trowel

LEVEL 60/E ELECTRIC

2 HP single phase motor,

230 V 50 Hz with double safety insulation,

Low tension switch with automatic stop device.

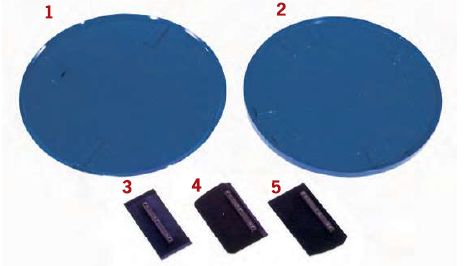

Blade and steel pan for Level 60 and 63 electric and gasoline

1. Slanted-edged steel pan, for normal trowelling

2. 90°-edged steel pan for wall edges

3. Finishing blade

4. 3mm thick combi blade

5. Rounded-edge blades for wall edges

Disk with large brushes of 63 cm diam.

For cleaning floors it can be quickly interchanged with the steel blades.

Brush made up of 5 wire brushes. Scrubbing disk supplied with five steel brushes with planet-like rotation

Nylon Scrubbing Disk

LEVEL 60 SERIES SPECIFICATION TABLE

|

Model |

LEVEL 60/E – ELEC. |

LEVEL 60 – ROBIN SUBARU |

LEVEL 60 – Honda |

|

Model Code |

PFLL60EA |

PFLL060R |

PFLL060S |

|

Rotor diameter mm |

600 |

600 |

600 |

|

Number of blades |

4 |

4 |

4 |

|

Finishing blades mm |

220x100 |

220x100 |

220x100 |

|

Roughing blades mm |

- |

- |

- |

|

Trowel disk diameter mm |

640 |

640 |

640 |

|

Blade rev rotation 1/min |

102 |

131 |

131 |

|

Motor |

230 V – 50 Hz |

Subaru Petrol EX16 |

Honda Petrol GX160 |

|

Motor Power kw (HP) |

1.5 (2) |

3.3 (4.5) |

4.0 (5.5) |

|

Starting |

Electric |

Recoil |

Recoil |

|

Fuel consumption l/h |

- |

1.2 |

1.4 |

|

Tank Capacity Ltr |

- |

3.5 |

3.6 |

|

Dimension L/W/H mm |

1,300 x 636 x 850 |

1,300 x 636 x 850 |

1,300 x 636 x 850 |

|

Weight Kg |

64 |

56 |

56 |

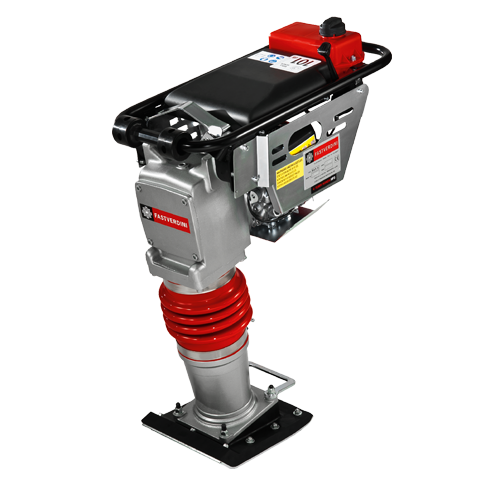

7. Tamping Rammer

FEATURES

• Transmission system and ramming parts in watertight oil bath: guarantees safe operation and minimizes servicing requirements.

• Ramming foot has ultra-efficient stroke and is self-adjusting to suit the type of material being compacted.

• Corrosion-proof fuel tank with filter, decanter, anti-overflow plug and breather.

• Controlled throttle lever ensures motor rpm is never exceeded.

• Compact handle with full shock absorbers for improved vibration damping.

• Foot plate in nodular cast iron, attached to nylon foot with sheet steel exterior coating; absorbs vibration and juddering throughout the structure and internal parts of machine.

• Parts move in steel and cast steel cylinders; aluminium hasn’t been used for this particular feature.

• Dimension of dry clutch (manufactured by Fast Verdini) specially designed to withstand severe wear and tear from the rammer.

• Motor driven by means of casehardened, ground helical spur gears; gear shaft supported by steel bushes built into the aluminium body, not on cover.

• Two drive system: petrol 4 strokes with HONDA motor, Diesel with YANMAR motor.

• Handling kit for easy transport (plastic castor as loading aid and handle on foot).

• New carter for engine protection.

RAN 6 HONDA (PETROL)

Heavy duty rammer with excellent yield, powerful, balanced and easy to handle, it ensures great productivity and compaction force. ACCESSORIES: transport trolley and lifting handle with drive roller.

RAN 6 ROBIN SUBARU (PETROL)

Heavy duty rammer with excellent yield, powerful, balanced and easy to handle, it ensures great productivity and compaction force. ACCESSORIES: transport trolley and lifting handle with drive roller.

|

Model |

RAN 6 HONDA |

RAN 6 ROBIN SUBARU |

|

Model Code |

PFCRAN60 |

PFCRAN6R |

|

Operating Weight Kg |

73 |

80 |

|

Motor |

Honda GXR120 |

Robin Subaru EH12 |

|

Power Kw (Hp) |

2.94 (4.0) |

2.94 (4.0) |

|

Ram width cm |

28 |

28 |

|

Ram length cm |

32 |

32 |

|

Ram stroke mm |

54 |

54 |

|

Number of blows/1’ |

700 |

700 |

|

Compaction force KN |

16 |

16 |

|

Compaction depth mm |

650 |

650 |

|

Advancement speed m/1’ |

12 |

12 |

RAN 7 HONDA (PETROL)

Heavy duty rammer with excellent yield, powerful, balanced and easy to handle, it ensures great productivity and compaction force. ACCESSORIES: transport trolley and lifting handle with drive roller.

HONDA 7 ROBIN SUBARU (PETROL)

Heavy duty rammer with excellent yield, powerful, balanced and easy to handle, it ensures great productivity and compaction force. ACCESSORIES: transport trolley and lifting handle with drive roller.

|

Model |

RAN 7 HONDA |

RAN 7 ROBIN SUBARU |

|

Model Code |

PFCRAN7H |

PFCRAN7R |

|

Operating Weight Kg |

80 |

86 |

|

Motor |

Honda GXR120 |

Robin Subaru EH12 |

|

Power Kw (Hp) |

2.94 (4.0) |

2.94 (4.0) |

|

Ram width cm |

28 |

28 |

|

Ram length cm |

32 |

32 |

|

Ram stroke mm |

72 |

72 |

|

Number of blows/1’ |

700 |

700 |

|

Compaction force KN |

16.6 |

16.6 |

|

Compaction depth mm |

650 |

650 |

|

Advancement speed m/1’ |

13 |

13 |

All rammers compact sand and fine gravel with varying results, but few can compact larger fragments of stone (20 – 40 cm) like

the RAN 6 and RAN 7; other rammers do not stay in one place when compacting this type of material, causing the operator to

lose control.

RAN 6 YANMAR (DIESEL)

Heavy duty rammer with excellent yield, powerful, balanced and easy to handle, it ensures great productivity and compaction force. ACCESSORIES: transport trolley and lifting handle with drive roller.

|

Model |

RAN 6 YANMAR |

|

Model Code |

PFCRAN6D |

|

Operating Weight Kg |

90 |

|

Motor |

Yanmar L48N |

|

Power Kw (Hp) |

3.5 (4.8) |

|

Ram width cm |

28 |

|

Ram length cm |

32 |

|

Ram stroke mm |

54 |

|

Number of blows/1’ |

670 |

|

Compaction force KN |

16.5 |

|

Compaction depth mm |

680 |

|

Advancement speed m/1’ |

12 |

RAN 7 YANMAR (DIESEL)

Heavy duty rammer with excellent yield, powerful, balanced and easy to handle, it ensures great productivity and compaction force. ACCESSORIES: transport trolley and lifting handle with drive roller.

|

Model |

RAN 7 YANMAR |

|

Model Code |

PFCRAN7D |

|

Operating Weight Kg |

98 |

|

Motor |

Yanmar L48N |

|

Power Kw (Hp) |

3.5 (4.8) |

|

Ram width cm |

28 |

|

Ram length cm |

32 |

|

Ram stroke mm |

72 |

|

Number of blows/1’ |

670 |

|

Compaction force KN |

17.2 |

|

Compaction depth mm |

680 |

|

Advancement speed m/1’ |

13 |

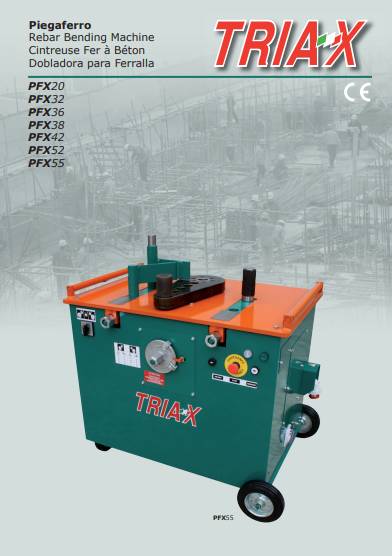

8. TRIA-X Bar Bender Machine

QUALITY AND SAFETY OF TRIAX REBAR BENDING MACHINE:

TRIAX produces electric bar bending machines since decades with a technology that makes very performing, reliable and safe. Our machines to bend concrete reinforcing steel bars are designed to provide maximum efficiency and ease of use which is extremely important in modern construction and building sites.

Triax reinforcement bar benders are 100% Made in Italy in fact as well as producing in our factory the whole machine (machining with CNC machines, welding, painting, assembly etc.) also the first choice components we buy (self-braking electric motors, electrical parts etc.) are all produced in Italy from trusted suppliers with whom we work since many years. In addition all the bar processing machines are fully tested before shipment and all this gives us the certainty that our rod bending machines have very high and constant quality standards over time.

Our goal is to give customers the best service in both sale and after-sales giving answers and shipping spare parts orders in very short time.

MODEL |

HP |

WORK |

BAR N. |

R55Kg/mm2 |

R65Kg/mm2 |

R85Kg/mm2 |

DIMENSION |

WEIGHT (KG) |

|

PFX20 SINGLE PHASE |

3 |

² |

1 |

Ø 18 |

740x610xh780mm |

90 |

||

|

2 |

Ø 14 |

|||||||

|

3 |

Ø 12 |

|||||||

|

PFX20 THREE PHASE |

3 |

² |

1 |

Ø 18 |

740x610xh780mm |

90 |

||

|

2 |

Ø 14 |

|||||||

|

3 |

Ø 12 |

|||||||

|

PFX32 SINGLE PHASE |

3 |

1 |

Ø 30 |

Ø 28 |

Ø 26 |

620x750xh900mm |

250 |

|

|

2 |

Ø 24 |

Ø 22 |

Ø 20 |

|||||

|

3 |

Ø 20 |

Ø 18 |

Ø 16 |

|||||

|

PFX32 THREE PHASE |

2 |

1 |

Ø 30 |

Ø 28 |

Ø 26 |

620x750xh900mm |

250 |

|

|

2 |

Ø 24 |

Ø 22 |

Ø 20 |

|||||

|

3 |

Ø 20 |

Ø 18 |

Ø 16 |

|||||

|

PFX36 THREE PHASE |

3 |

1 |

Ø 32 |

Ø 30 |

Ø 28 |

650x850xh900mm |

280 |

|

|

2 |

Ø 26 |

Ø 24 |

Ø 22 |

|||||

|

3 |

Ø 20 |

Ø 18 |

Ø 16 |

|||||

|

PFX38 THREE PHASE |

4 |

1 |

Ø 34 |

Ø 32 |

Ø 30 |

650x850xh900mm |

380 |

|

|

2 |

Ø 28 |

Ø 26 |

Ø 24 |

|||||

|

3 |

Ø 22 |

Ø 20 |

Ø 18 |

|||||

|

PFX42 THREE PHASE |

4 |

1 |

Ø 36 |

Ø 36 |

Ø 34 |

650x850xh900mm |

420 |

|

|

2 |

Ø 30 |

Ø 28 |

Ø 26 |

|||||

|

3 |

Ø 26 |

Ø 24 |

Ø 22 |

|||||

|

PFX52 THREE PHASE |

5.5 |

1 |

Ø 42 |

Ø 42 |

Ø 38 |

700x900xh950mm |

460 |

|

|

2 |

Ø 36 |

Ø 34 |

Ø 32 |

|||||

|

3 |

Ø 28 |

Ø 26 |

Ø 24 |

|||||

|

PFX55 THREE PHASE |

5.5 |

1 |

Ø 52 |

Ø 48 |

Ø 44 |

1120x780xh920mm |

650 |

|

|

2 |

Ø 40 |

Ø 38 |

Ø 34 |

|||||

|

3 |

Ø 34 |

Ø 30 |

Ø 26 |

STEEL BAR BENDING MACHINE DESCRIPTION:

• Self-braking electric motor characteristic that greatly extends the life of the motor that do not undergo electric shocks while reversing rotation.

• Two-stage epicyclical gear unit with gears in constant oil bath that allows carrying any bending reducing much the mechanical effort.

• Automatic graduated regulator with which it is possible to accurately determine the bending angles, a much more accurate and faster system of the old system with holes around the bending disk.

• Bending disk rotating in both directions, after bending the reinforcing steel bar or steel round bar will automatically return to the starting point.

• Electric dual controls with foot pedal that allows great freedom of movement to the operator in selecting the most suitable working position in respect to the machine.

• Safety micro switch on the door which, also with connected power, switches off the machine if the door is open as required by current safety regulations.

• All electric controls work with low voltage 24V according to current regulations.

REBAR BENDING MACHINES PRODUCED VERSIONS:

• Electric rebar bender as per EC norms. Designed and built following the criteria necessary to meet safety requirements established by current Machinery Directive 2006/42/EEC.

• Electric rebar bender No EC.

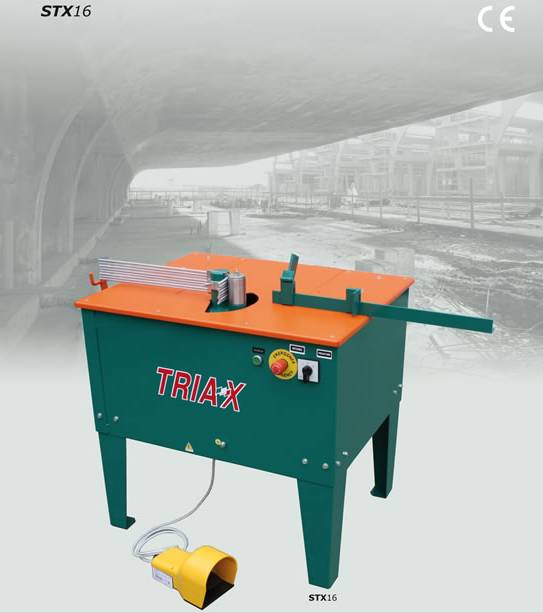

Stirrup Bending Machine

Machines for high productions of stirrups

STX16

MODEL |

HP |

WORK |

DIAMETER |

BAR N. |

DIMENSION |

WEIGHT (KG) |

||

R55 Kg/mm2 |

R65 Kg/mm2 |

R85 Kg/mm2 |

||||||

|

STX16 SINGLE PHASE |

3 |

² |

Ø 16 |

1 |

1 |

1 |

900x700xh860mm |

180 |

|

Ø 14 |

2 |

2 |

1 |

|||||

|

Ø 12 |

3 |

3 |

2 |

|||||

|

STX16 THREE PHASE |

3 |

² |

Ø 10 |

5 |

4 |

3 |

900x700xh860mm |

180 |

|

Ø 8 |

8 |

7 |

6 |

|||||

|

Ø 6 |

9 |

8 |

7 |

|||||

QUALITY AND SAFETY OF TRIAX STIRRUP BENDING MACHINE:

TRIAX produces rebar stirrups machines since 1993 with a technology that makes them very fast and reliable over time. Our machines for high productions of stirrups have been designed to provide maximum efficiency to those who have to produce large amounts of brackets as they allow to bend simultaneously up to 9 rebars of 6mm diameter (see technical characteristics table).

TRIAX stirrups bender is 100% Made in Italy, we produce in our factory the whole machine (machining on CNC machines, welding, painting and assembly) and the high-quality components that we buy (electric motor, electric parts and so on.) are all produced in Italy from trusted suppliers with whom we work since many years.

Furthermore all machines are carefully tested before shipment; all this gives us the certainty that we can keep high and constant quality standards over time.

Our goal is to give customers the best service in both sale and after-sales ensuring rapid responses and very fast spare part shipments.

STIRRUPS MACHINE DESCRIPTION:

• Warm reduction gearbox in constant oil bath that allows to carry any bending greatly reducing mechanical stress.

• Regulation system that allows to accurately determine the bending angles of the steel stirrups.

• Bending arm that after each bend automatically returns to the starting position.

• Electric dual controls with foot pedal that allows great freedom of movement to the operator in selecting the most suitable working position in respect to the machine.

• All electric controls work with low voltage 24V according to current regulations.

REBAR STIRRUPS MACHINE PRODUCED VERSIONS:

All TRIAX stirrup bending machines are designed and built according to the criteria necessary to meet safety requirements established by current Machinery Directive 2006/42/EEC.

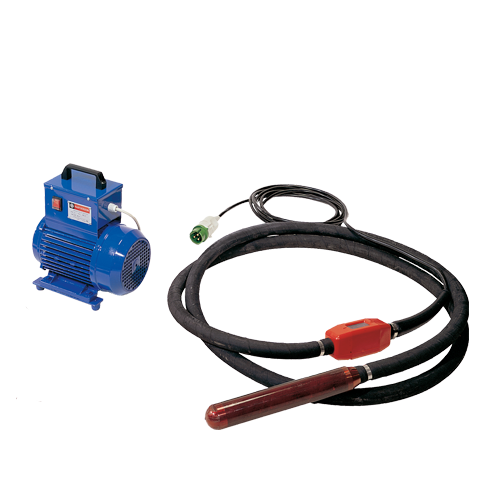

9. Vibrators and Convertors

NON STOP POWER

Test Fast Verdini vibrators’ power for yourselves. First turn on the vibrator then place the needle with one foot. The Ergoviplus Vibrator continues non-stop without decreasing the number of rpm; other similar vibrators available on the market will stop when put the same test.

ERGOVIPLUS SERIES

Ergoviplus range particular care has been taken during production for the above models in the application and choice of bearings, the type of steel employed, the casing thickness, type of switches (obviously water-tight) and all electrical components. The high frequency motor is built into the vibrating needle (vibration frequency 12,000 per min.) has a length and power highly superior in comparison with other vibrators. The production line includes models T27X, T40X, T55X and T75X with diameters of 38, 52, 65 and 85 mm. respectively.

ERGOVIPLUS

|

Type |

Needle Ø mm. |

Needle Length mm. |

Frequency Hz |

Volts |

No. of vibrations 1/min. |

Centrifugal Force Kg |

Cable Length |

Hose Length |

Max Mc/h |

Primary current Amp. |

Secondary current Amp. |

|

T27X |

38 |

315 |

200 Hz |

46 |

12,000 |

150 |

10 |

5 |

12/14 |

1 / 2 |

4 |

|

T40X |

52 |

395 |

200 Hz |

46 |

12,000 |

400 |

10 |

5 |

15/20 |

6 / 7 |

11 |

|

T40CX |

52 |

395 |

200 Hz |

46 |

12,000 |

400 |

9 |

4 |

15/20 |

6 / 7 |

11 |

|

T55X |

65 |

420 |

200 Hz |

46 |

12,000 |

600 |

10 |

5 |

25/28 |

12 |

22 |

|

T75X |

85 |

470 |

200 Hz |

46 |

12,000 |

1000 |

10 |

5 |

35/38 |

13 |

32 |

CONVERTERS

Three phase from 2.75 – 6.8 KVA and single-phase from 1.2 – 2.5 KVA are available. Single Phase converters are connected with 230V 50Hz which is then transformed into three phase 46V 200Hz.

KIT: Cpmplete with handle, base support, switch, 1 Mtr. Of 4-ply electric cable 1.5 sq.mm. and electrical plug. Upon request three-phase converters can be equiped with thermal protection.

+94 11 2 823 600 / +94 11 2 768 300

+94 11 2 823 600 / +94 11 2 768 300